Inventory is at the center of business. It is powerful enough to make or break a sale, it impacts turnaround time for customers, and can even affect profitability. Some companies can have too much inventory, others not enough.

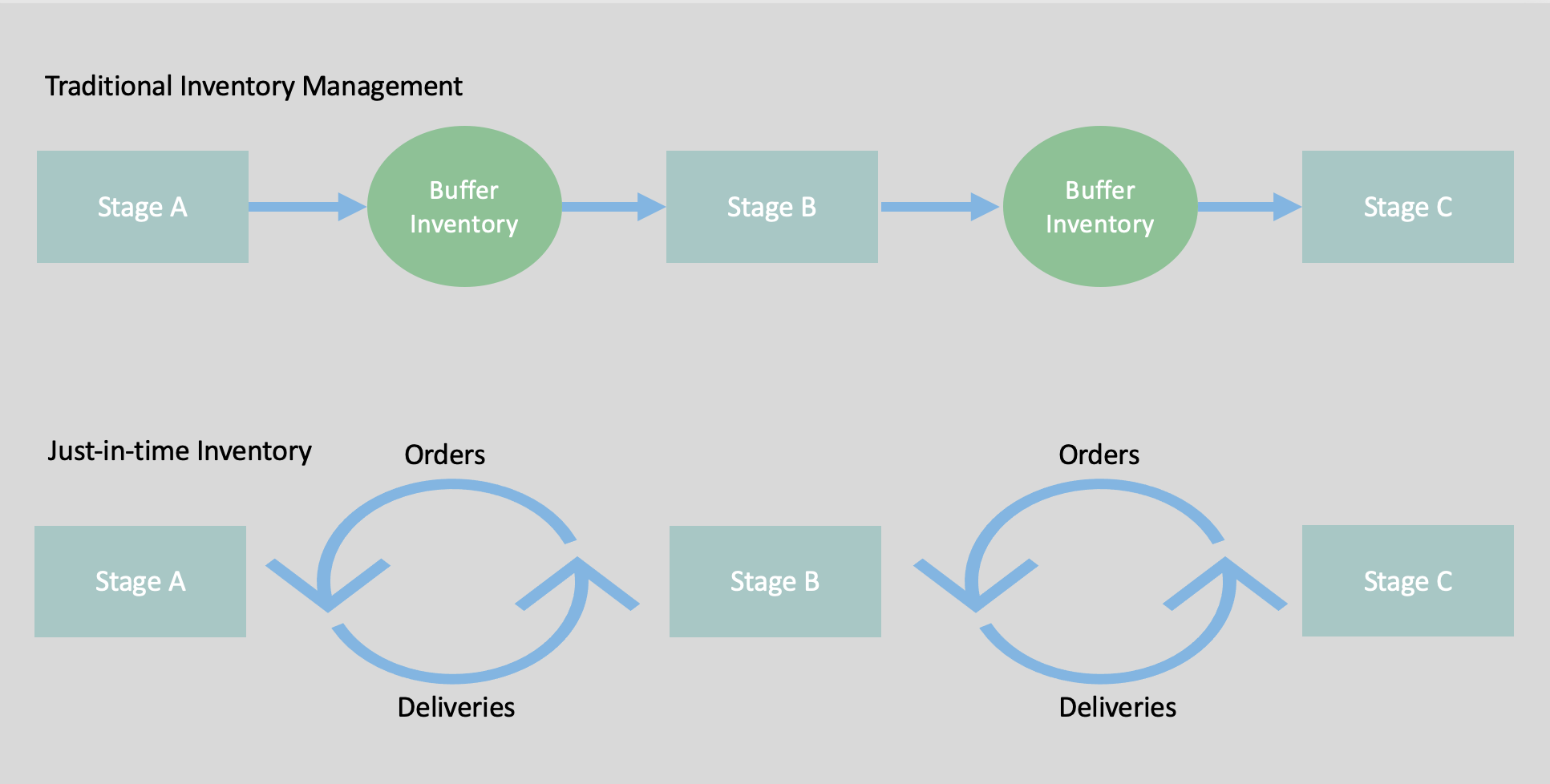

Traditionally, businesses manage inventory through forecasting and maintaining safety stock levels to support emergencies and surprise business. Throughout the years this traditional inventory management style has taken a turn, and companies are applying the just-in-time (JIT) inventory system. This concept was founded on the idea that keeping large amounts of inventory is a waste. A waste of space, a waste of working capital and a waste of inventory.

Disadvantages of Traditional Inventory Management

Waste of real-estate space. Whether you own or rent your warehouse space, one could say keeping large amounts of inventory on the warehouse floor is a waste of space. In some cases, companies could reduce the amount of warehousing they are using by switching to just-in-time inventory. If you own the warehouse, you could rent the space and turn it into income. This area could also be used to expand manufacturing equipment or office space, if needed.

Waste of working capital. Working capital is the capital of the business used in its day-to-day trading operations. Working capital is calculated as the current assets minus the current liabilities. JIT is designed to keep inventory levels low, so the investment in working capital is minimized.

Waste of inventory (increasing scrap). JIT is designed to only keep what you need for the next production run. With the traditional inventory system, inventory can go bad or end of life, causing a company to have to scrap the inventory and take a loss financially.

Disadvantages of Just-In-Time Inventory

Increased risk for supply chain shortages or manufacturing delays. Over the past few years here in the Midwest we have seen the direct impact of mother nature. In 2018, extreme cold and snow reached across the United Stated causing delays in trucking and inventory delivery. Companies using JIT were scrambling to find inventory to continue to meet customer due dates and needs. The shortage in supply caused a ripple effect through many industries. Over the last five years I have seen drastic changes in the paper industry caused by paper mill closures, this has lead to inventory shortages, longer lead times and missed due dates.

Long lead times can cause missed deadlines. Reducing this risk comes easy to some with a well-oiled material resource planning (MRP) system. However, if your customer contract promise date is three weeks, and it takes six weeks to receive inventory from your vendor, you have already missed your promise date before you received your order.

Unable to fulfill the surprise business. One of the biggest disadvantages of JIT is being unable to meet the needs of the awesome new business that the sales team brought in. Many times, the sales team brings in a new customer and wants to get the product out the door right away to impress the customer and beat the competitor. With JIT inventory, you will not have the ability to meet the needs of excited new customers without possibly pushing your current customers aside.

Increased IT expenses. While this issue isn’t with just-in-time directly, many companies do not have the necessary tools for planning to handle JIT. Planning and communication company-wide is a necessity to keep production moving with the inventory arriving at exactly the right time. It would be beneficial to have a sophisticated MRP or ERP that can help manage scheduling and planning.

Customer satisfaction. Hopefully this would never be an issue, but unfortunately it is a common side effect of just-in-time inventory. When any of the above obstacles occur, customer satisfaction is directly affected.

Now the big question for all companies, do the risks outweigh the benefits? Many companies are moving to a mix of just-in-time inventory and traditional inventory management. One may choose to keep the traditional method for specific raw materials that have a large lead-time or are hard to procure, while reducing quantities in materials that are easy to acquire. Depending on who you are, what you do, and where your suppliers are located can impact your inventory tracking methods.